GrindingHub: Demonstrating Excellence in Precision Work

Precision work constitutes a specialized segment of industrial operations that demands a high level of technical expertise and sophisticated knowledge. Many enterprises continue to rely on manual methods, which can be economically burdensome and less consistent in quality. However, the integration of automated machinery offers significant advantages, including enhanced efficiency, speed, and uniformity. GrindingHub 2022, an upcoming event organized by prominent industry stakeholders, will provide companies with insights into the most advanced technological solutions for precision work.

Continuous Operation: A Strategic Imperative

In today's competitive landscape, the ability to operate continuously, 24/7, is a key differentiator for many enterprises. This is particularly true for large-scale production processes involving turning, milling, and drilling operations. The trend towards uninterrupted productivity is now extending to precision work applications. At GrindingHub, participating companies will present innovative strategies to optimize the performance and reliability of precision machinery.

Robotic Solutions for Enhanced Surface Finishing

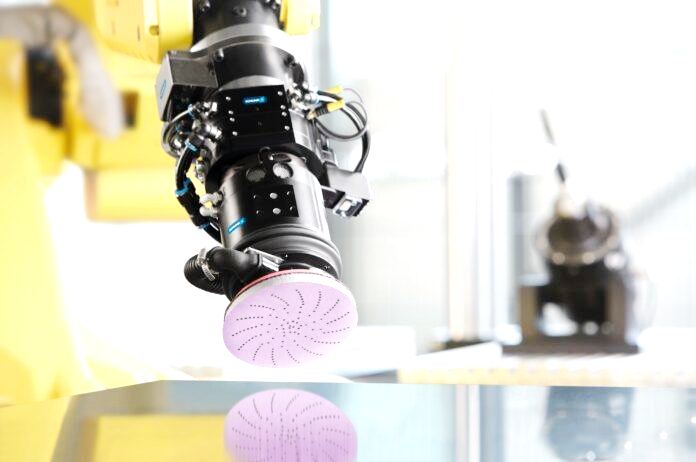

The production of highly polished surfaces is critical in industries such as automotive and aerospace engineering. While manual methods have traditionally been employed for this purpose, robotic systems offer superior capabilities in terms of speed, precision, and consistency. Schunk, a leading manufacturer of robotic machinery, has developed specialized tools designed to ensure flawless surface finishing. One such tool is a robotic sander that maintains a constant contact point, guaranteeing a smooth and uniform surface finish. Additionally, Schunk's robotic grinding and polishing systems are capable of processing irregularly shaped components with remarkable efficiency, thereby reducing the need for multiple tools and minimizing operational costs.

Daniel Mayer, a representative from Schunk, emphasized the company's commitment to not only providing state-of-the-art machinery but also offering comprehensive support in their implementation. Schunk's services include rigorous testing of equipment on client-specific materials to ensure optimal performance and reliability.

Achieving Complexity with Precision

The fabrication of intricate components, such as those required for automotive and aerospace applications, necessitates an exceptionally high level of precision. Modern precision machines are equipped with advanced communication protocols that enable seamless coordination and synchronization. This ensures that all elements of the production process are aligned to achieve the desired level of accuracy.

Marie-Sophie Maier-Wember, a representative from Haas, highlighted the user-friendly nature of their machinery and its capacity to produce superior quality components. Haas' precision machines are equipped with sophisticated software that facilitates adaptive adjustments, ensuring that each component meets the exact specifications required by the application.

Collaborative Machinery: The Future of Automation

The integration of collaborative machinery represents a significant advancement in the field of automation. Companies like Blohm Jung are pioneering the development of interconnected machines that can operate autonomously without human intervention. These systems are equipped with advanced communication interfaces that facilitate real-time data exchange and coordination.

Stefan Springer, a spokesperson from Blohm Jung, underscored the benefits of collaborative machinery in enhancing operational efficiency. By providing a centralized view of machine performance, these systems enable prompt identification and resolution of any issues, thereby minimizing downtime and optimizing productivity.

Conclusion

GrindingHub 2022 serves as a premier platform for industry professionals to explore the latest advancements in precision machinery and learn how to leverage these technologies to enhance their operations. The event, scheduled to be held in Stuttgart from May 17 to 20, 2022, is organized by key stakeholders in the industry. Given the strategic importance of grinding processes in the German manufacturing sector, events like GrindingHub play a crucial role in disseminating cutting-edge solutions and fostering innovation.