Trends in Grinding Technology: Electric Mobility, Digitalization, and Automation

The field of grinding technology is undergoing significant transformation due to the advent of electric mobility, digitalization, and automation. GrindingHub 2022, a prominent trade fair held in Stuttgart from May 17 to 20, 2022, serves as a platform for industry experts and leaders to present cutting-edge technologies and methodologies shaping this rapidly evolving sector.

Impact of Electric Vehicles on Grinding Technology

The rise of electric vehicles is revolutionizing the automotive industry, particularly in the production of engine components. Electric vehicles demand gears that are lightweight, highly precise, and robust. Liebherr-Verzahntechnik GmbH has pioneered advanced grinding techniques to meet these stringent requirements. By employing specialized grinding worms, the company enhances the durability and efficiency of gear production, significantly reducing operational costs and time.

Enhancing E-Bike Component Efficiency

The manufacturing of e-bikes necessitates the production of precise and efficient components. Liebherr employs specialized clamping systems to ensure the accuracy of small, critical parts during the manufacturing process. The company's machinery is calibrated to guarantee consistent roundness and dimensional accuracy, essential for the optimal performance of e-bike components. Rigorous quality control measures, including precision testing, ensure that each component meets the highest standards, thereby instilling confidence in the product's reliability.

Noise Reduction in Electric Car Gears

Electric vehicles require gears that operate smoothly at high speeds, up to 16,000 revolutions per minute. Friedrich Wölfel from Kapp Niles emphasizes the importance of noise reduction, especially at high velocities where other environmental noises may mask gear noise. To achieve this, Kapp Niles utilizes a specialized grinding process that ensures the smoothness of gears. Automated systems equipped with sensors continuously monitor the grinding process, identifying and rectifying any irregularities in real-time. This approach guarantees the production of high-quality gears without the need for subsequent manual inspections.

Innovations in Tool Grinding Techniques

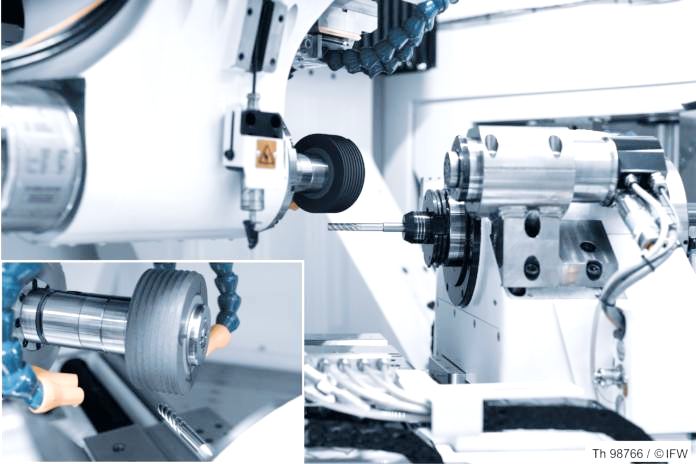

The field of tool manufacturing is also experiencing significant advancements. The Institute of Production Engineering and Machine Tools at Hanover is developing innovative grinding methods, including computer-aided prediction of tool shapes before production. This predictive modeling enhances the precision of tool designs and streamlines the manufacturing process.

The institute is also investigating the operational parameters of grinding wheels to optimize their utilization and reduce waste. Laser sensors are employed to continuously monitor the condition of grinding wheels, ensuring they are sharp and free of defects. This proactive approach extends the lifespan of grinding wheels and enhances tool efficiency.

Significance of Digitalization and Automation

Dr. Stefan Brand from the Vollmer Group highlights the transformative impact of digitalization on the grinding industry. Vollmer has developed a comprehensive data analytics system that enhances the efficiency and precision of grinding processes. This system provides users with actionable insights, enabling them to make informed decisions and optimize operational workflows.

Digitalization and automation are integral to modern grinding practices, particularly in tool sharpening and manufacturing processes. GrindingHub 2022 serves as a platform for industry stakeholders to showcase the latest advancements in these areas, fostering collaboration and innovation on a global scale.

Revolutionizing Cutting Tool Grinding

Traditional methods of grinding cutting tools are reaching their limitations. The Institute of Production Engineering and Machine Tools is pioneering a new approach that utilizes a single tool to simultaneously grind all edges of a cutting tool. This integrated grinding process significantly reduces manufacturing time and enhances the quality of cutting tools, minimizing wear and tear during production.

About GrindingHub 2022

GrindingHub 2022 is a groundbreaking trade fair organized by the German Machine Tool Builders' Association (VDMA), Messe Stuttgart, and the Swiss Association of Mechanical and Electrical Engineering Industries (VDMA Schweiz). It is the inaugural event dedicated to grinding technology, featuring cutting-edge solutions and innovations from leading industry professionals. The fair, scheduled to be held biennially, serves as a global hub for knowledge exchange and technological advancement in the grinding sector.

Grinding is a crucial manufacturing process in Germany, contributing significantly to the country's industrial prowess. In 2020, the grinding industry generated machinery worth 870 million euros, with approximately 80% of these exports destined for international markets. Germany, Japan, and Switzerland are among the leading manufacturers of grinding machines, with a combined value of 4.9 billion euros recorded in 2019. GrindingHub 2022 provides a platform for industry participants to present their innovations, explore emerging technologies, and drive the continued growth and development of the grinding sector.